Iso Container Corner Castings Houston

Question: This question relates to ISO tank container dimensions.“ We are going to set a concrete foundation for our tank container which we will use for storage purposes. Is a 20′ ISO tank exactly 20′ long? And what is the exact width? Intonation In Context Rapidshare Library. ” Tank Guru: Please see attached.

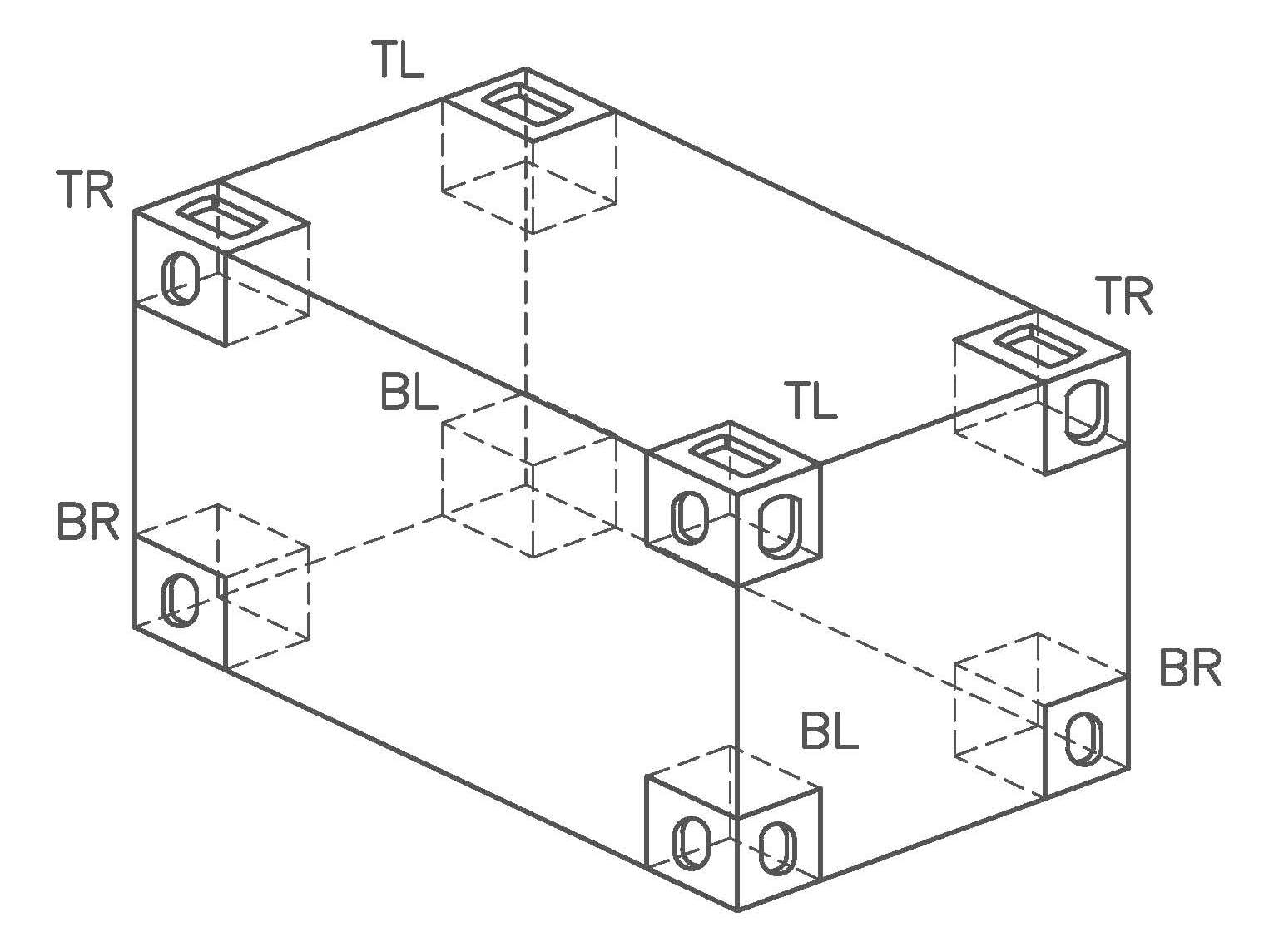

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview. Manual twistlocks. The main means of connection is through the use of a twist lock designed to go into one of the holes of a corner casting Download shipping container connection Dimensions: Dimensions 48' & 53' Stacking Cones for Containers Container Stacking Cones from PNW Equipment, Inc. The proprietary.

You will note that a 20′ tank container is actually 19′-10.5″ long from end-to-end (6058 mm). The overall width is 8′ (2438 mm) and both of these dimensions refer to the distance from the outside faces of the corner castings.

A standard tank container is considered a “1CC” shipping container as defined by ISO 668 (). Center-to-center of the holes in the bottom castings are 5853mm and 2259mm, respectively for length and width. We sell a lot of these portable tanks into storage service, because it’s hard to find the same value for a stainless steel, pressure-rated tank.

Ballast is necessary in ships for stability, balance, trim and to otherwise keep them upright because the alternative is not pleasant. The amount of ballast necessary varies based on the type of ship and the amount of cargo if any.

Unity Pro Crack Mach3. Legend has it that many buildings and roadways in the Colonies were constructed out of brick and cobblestones that came over from Europe as ballast on ships. Alas, it is only a legend, as the vast majority of buildings and roadways were constructed out of native bricks and cobblestones. Not enough ballast came over to make a significant dent in the infrastructure of the time. But enough came over to end up in a few historic landmarks and provide fodder for the legend. The main reason this type of ballast came over was because more cargo went east to Europe at the time than the other way around.

How times have changed, now more comes to America than leaves. Hold that thought for later. More recently, in this past century, ballast from England was instrumental in the construction of a New York City landmark. During the Second World War the United States provided an Atlantic lifeline to England supplying men and materials for the war effort. Canadians escorted the allied convoy ships and for a time Canada had the third largest navy in world. Many of the convoy ships disembarked in Bristol, England, a major port city.

The ships “had no British goods to replace them on the return trip, and needed ballast for stability.” The Luftwaffe solved the ballast problem by bombing the city to near devastation. The brick rubble from the Luftwaffe bombing provided the ballast for the empty convoy ships returning to America. In New York City this ballast was used to build East River Drive.

Our story now takes us to North Carolina and a local “good ole boy”. Malcom McLean, armed with a high school education, bought a secondhand truck from savings earned pumping gas and started a trucking company that ended up changing the world. He wanted a way to move cargo on ships without having to unload his trucks. He figured he could just load his trucks onto ships, strap them down, and be done with it.

That didn’t work very well. But this “good ole boy” didn’t’ give up. He needed an engineer to make things work. An old school engineer. My kind of engineer. Winrar Password Remover 2013 Free Download No Survey. Keith Tantlinger, a mechanical engineering graduate from the University of California, Berkeley who worked for the Douglas Aircraft Company during the war building B-17 bombers solved McLean’s problem. Disconnect the truck payload from the truck chassis.

Have a bunch of stackable boxes that could go from a truck chassis onto a railroad car or onto a ship. This was not a new idea, but Tantlinger made it work by designing the boxes and the method of securing the boxes and the method of lifting the boxes. He created the “intermodal freight container”. Intermodal because it went from ship to rail to truck without unloading and reloading the contents.

Comments are closed.